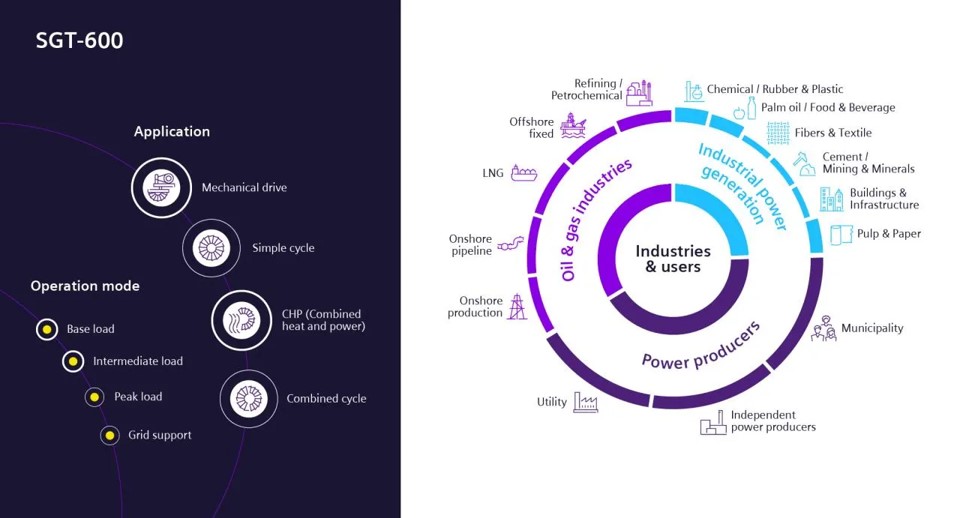

The SGT-600 combines robustness with an excellent maintenance program for high availability and low costs for operation.

High reliability, excellent fuel flexibility and third-generation DLE make the SGT-600 a perfect choice for applications like industrial power generation in combined heat and power (CHP), and combined circle power plants (CCPP), onshore oil and gas power generation, as well as mechanical drives.

The SGT-600 offers best-in-class fuel flexiblity that allows for high content of inert gases, hydrogen and heavy hydrocarbons:

- Ethane 100%

- Propane 100%

- Butanes and heavy alkanes 15%

- Hydrogen up to 60%

- Nitrogen 40%

- H₂S ≤ 3.5%

The SGT-600 features a third-generation dual-fuel Dry Low Emissions (DLE) combustion system:

- NOₓ emissions level < 9 vppm

- CO emissions level < 20 vppm

- Turn down 50% load

- Same DLE system for dual and liquid operation

- NOₓ emissions on liquid fuels < 58 ppmvd

- CO emissions on liquid fuels < 25 ppmvd

- Turn down 50% on liquid fuels

- Dual-fuel DLE capability with fuel changeover capability (gas to liquid fuel and liquid fuel to gas) on load

The SGT-600 features a reliable, robust and easily maintainable design for maximized uptime.

Reliability > 99%

On-site or off-site maintenance

24-hour swap capability

17 maintenance days in 17 years

34,000 equivalent operating hours (EOH) between hot section inspections

Part load operation increases the time between overhauls

Thanks to a long lifetime with maximized uptime, low life cycle cost and easy servicability, the SGT-600 offers you a high lifetime profitability. The robust industrial design offers a low degradation over time.

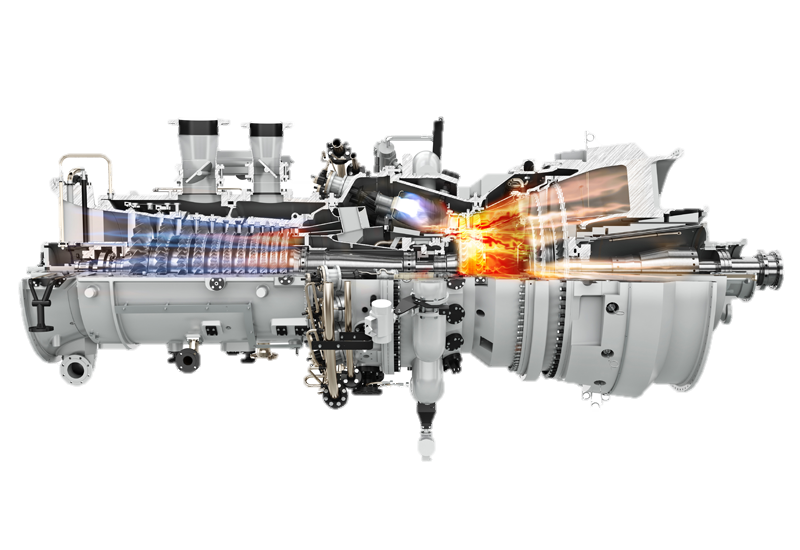

Ingenious design to the core

The SGT-600 offers you best-in-class availability thanks to a robust and reliable design.

The compact twin-shaft engine is easy to maintain and allows for flexible opeation.

Using the same design for power generation and mechanical drive increases the operational experience.

Compressor

Compressor

The SGT-600 core engine features a 10-stage flow transonic compressor with variable guide vanes for robust operability and optimizied performance over a wide range of operating conditions.

Free power turbine

Free power turbine

The 2-stage uncooled free power turbine offers you a nominal shaft speed of up to 7,700 rpm.

For mechanical drive, it may operate at 50 to 105% of the nominal speed.

The blades use interlocking shrouds for extra robustness.

SGT-600 power generation and mechanical drive packages

Thanks to the compact architecture, the SGT-600 package offers you a small footprint. The package has a modular and flexible design and features single-lift capability.

The driver for both power generation and mechanical drive package is the same.

A gas turbine package includes:

Gas turbine, enclosure, base frame, air intake, exhaust, lubricating systems, starter system, vibration monitoring system, firefighting system, package ventilation system, instrumentation, gas detection, fuel systems, gearbox (if needed).

Power generation package

Power generation package

The SGT-600's ability to handle sudden load changes and its high exhaust temperature make it ideal for simple cycle, combined cycle, cogeneration, and other heating applications.

- Small footprint for easy fitting

- Modular and flexible package design

- Single-lift capability

Mechanical drive package

Mechanical drive package

The SGT-600 mechanical drive packages offer long lifecycles and can withstand extreme climates ranging from desert heat to arctic cold, oil platforms, and harsh industrial environments.

-Variable power turbine speed: 50 to 105%

-High load on low-power turbine speed

-Maintains efficiency at part load

-Low emissions at part load

SGT-600-based power plants

For combined cycle and cogeneration (combined heat and power-CHP), we offer a broad range of power plant configurations and scopes based on the SGT-600 gas turbine. For combined cycle, 1x1 or 2x1 configurations are part of the standardized portfolio.

Excellent CC and CHP efficiency

Good combined cycle performance: In a 2x1 combined cycle configuration, the power output is 73.3 MW(e) at a net plant efficiency of 50.9%.

Comprehensive services to support you

Our comprehensive portfolio of services provides low life cycle cost and optimum performance throughout the turbine's life cycle: Long Term Programs (LTP), overhaul service, field service, spare parts, service exchange, remote diagnostic service, and modernization and upgrades.

With only 17 scheduled maintenance days over a 17-year service cycle, the SGT-600 provides highest operational availability.

Whether scheduled service or short-term support, our specialists are there for you, on-site or off-site all over the world. Our 24-hour global help desk ensures you peace of mind.

Easy on-/off-site maintenance

Easy on-/off-site maintenance

The SGT-600 is designed for maximized serviceability.

Both on-site maintenance and a gas generator removal for off-site maintenance are possible.

Gas generator swap is performed within 24 hours.

Remote diagnostic service

Remote diagnostic service

Our remote diagnostic service helps you to detect faults at an early stage and prevents outages.

The service includes online monitoring, expert performance data analysis, and fleet data comparisons.

Designed for easy serviceability

Designed for easy serviceability

Burners are accessible from the outside for easy replacement.

Compressor casing is horizontally split, and the turbine casing is vertically split between gas generator and power turbine.

Multipe boroscope holes allow for internal visual inspection of the compressor.

High fuel flexibility

The SGT-600 offers best-in-class fuel flexibility that allows for high content of inert gases, hydrogen and heavy hydrocarbons:

Ethane 100%

Propane 100%

Butanes and heavy alkanes 15%

Hydrogen up to 60%

Nitrogen 40%

H₂S 3.5%

Features:

Available with both conventional and DLE combustion systems

Gaseous and liquid fuels on-load changeover

Third-generation DLE system

Best-in-class NOₓ emission levels

The SGT-600 requires low gas supply pressure at site:

24.5 bar(a) / 355.5 psi(a).

Low emission capability

The combustor and burner design give world-class emission performance over a wide load range and are capable of ≤ 9 ppmvd NOₓ emission levels.

Low emission levels are also received on liquid fuel without need of water injection.

Emissions for 100 -50% load, NOₓ at 15% O₂:

Natural gas: ≤ 9 ppmv

Diesel No. 2: ≤ 42 -58 ppmv

Emissions for 100 -50% load, CO at 15% O₂:

Natural gas: ≤ 10 -80 ppmv

Diesel No. 2: ≤ 10 -80 ppmv

(Emissions depend upon site conditions, required load range and other project-specific data.)

Performance data for simple cycle power generation

|

Gross power output: |

24.5 MW |

|

Fuel: |

Natural gas, liquid fuel, dual fuel

|

| Frequency: |

50/60 HZ |

| Gross efficiency: |

33.6% |

| Gross heat rate : |

10,720 kJ/kWh (10,161 Btu/kWh)

|

| Turbine speed : |

7,700 rpm |

| Pressure ratio: |

14.0 : 1 |

| Exhaust mass flow : |

81.3 kg/s (179.2 lb/s) |

| Exhaust temperature : |

543 °C (1,009 °F) |

| NOₓ emissions² : |

≤ 9 ppmvd |

All performance values are based on standard design, ISO ambient conditions and natural gas fuel. No intake or exhaust loss. | ¹1 Natural gas, other gases within specification, liquid fuel (Diesel No. 2) and dual fuel (gas and liquid) | ²NOₓ emissions at 15% O₂ on fuel gas (with DLE)

SCC-600: Performance data for combined cycle power generation

| Siemens combined cycle power plant |

SCC-600 1x1 |

SCC-600 2x1 |

Gross power output |

36.5 MW(e) |

74.2 MW(e) |

Gross plant efficiency |

50.7% |

51.6% |

Gross heat rate |

7,105 kJ/kWh (6,734 Btu/kWh) |

6,981 kJ/kWh (6,616 Btu/kWh) |

Number of gas turbines |

1 |

2 |

Note: All combined cycle performance is based on 2 pressure, no reheat.

Physical dimensions and weight

Dimensions exclude inlet filter housing and exhaust stack. For power generation, the AC generator is included. For mechanical drive, the driven equipment is excluded.

Designed for easy serviceability

Designed for easy serviceability